Facilities Management—Water

Conservation Facilities Management—Water

Conservation

Hospitals and other healthcare facilities are significant users of water. Adopting better water management practices can have a significant impact, especially in populated areas where water treatment and distribution, and wastewater treatment infrastructure, are often barely capable of meeting demand. This section highlights various uses of water at healthcare facilities, and identifies practices and technologies that can significantly reduce their water use.

Introduction

Water conservation makes good sense for healthcare facilities. Reducing water use can lead to major savings in terms of lower water and sewer bills. In addition, many water conservation techniques can be directly linked to reduced energy consumption, resulting in even greater cost savings.

More fundamentally, water is a highly valuable national resource. A reliable supply of clean fresh water is necessary to sustain our population and our familiar way of life. We are all responsible for protecting it, but not everyone has embraced this responsibility -- per capita water use in the U.S. is higher than in any other developed country. There is no good reason that our typical practices have become so much more wasteful than those of our counterparts in other countries. We have simply made a long series of bad choices, based on the erroneous perception that fresh water would always be available in unlimited abundance, no matter how large our population grew, and how much process water our technological society would grow to demand. We have not invested in efficient equipment, and many of our habits and practices still reflect the thoughtlessly wasteful attitudes of decades ago.

If social responsibility is not sufficient reason for conserving water, consider that the U.S. Green Building Council's Leadership in Energy and Environmental Design (LEED) rating system offers up to five LEED water-efficiency credits:

- two for reducing potable water use for irrigation

- one for reducing potable water use for sewage conveyance; and

- two for reducing potable water use inside a building.

Many cities now encourage LEED certification, and some require it outright for city-funded projects.

Healthcare Facility Water Use

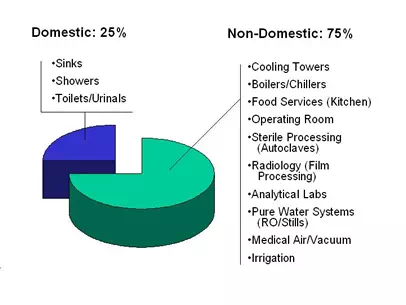

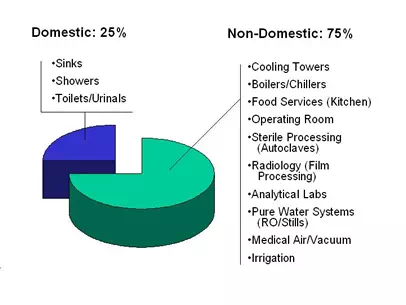

Healthcare facility water use varies widely depending on type, size, geographical location, and water use equipment/practices. A water use study published in 2002 showed a range of water use from 68,750 to 298,013 gallons per year per bed for hospitals in the size range of 133 to 510 beds. The same study indicated that hospitals typically have the following broad breakdown of water use:

Source: Practice Greenhealth Green Guide for Health Care Series - Water Conservation Strategies.

Water Conservation Programs

Hospitals that have conducted successful water use reduction programs have been able to reduce water use by approximately 20 to 30%. For large facilities, this can translate to over $100,000 per year savings in water, sewer and energy costs. Based on published reports, healthcare facilities that implement water conservation changes can expect a return on investment (ROI) in the range of approximately 25% - 40%. However, to achieve such dramatic savings requires a systematic approach. Recommended steps include:

- Audit current water use. Install water meters at strategic locations in the facility. Read/record water readings weekly (or more frequently at first) and analyze the data. Look for high water use areas, trends, and unusual occurrences.

- Identify water conservation opportunities, including low hanging fruit (drips, leaks and unnecessary flows), changes to operations (e.g., improved practices in cleaning, laundry and kitchen), and opportunities requiring engineering/equipment solutions (toilets, sterilizers, boiler, chillers, etc.).

- Determine cost of opportunities and potential return on investment.

- Prioritize water conservation opportunities.

- Develop a phased plan that fits your budget.

- Obtain funding (revise plan, if necessary).

- Implement plan.

- Measure and document success.

A healthcare facility may undertake a water conservation project using internal resources, or may choose to hire an engineering company that specializes in this subject. Outside assistance is especially helpful when it comes to analyzing equipment retrofit and replacement projects, since new technologies are constantly coming into the market and their true effectiveness is difficult to ascertain from product literature. In addition, outsiders may make it easier to get your project funded because they can organize and format your data in a way that sells your program to management. Some consultants are willing to negotiate “performance contracts” that are structured to guarantee reductions in operational costs over time. That can also be a good selling point when seeking approval. At least one company offers a “no capital” five-year program that allows hospitals to treat the capital cost as an operating expense.

Water Conservation Opportunities

Wherever water is used in a healthcare facility, there is probably an opportunity for conservation. Here are some ideas.

The Basics

- Increase employee awareness of water conservation (educate staff, seek suggestions, assign responsibility, post signs, etc.).

- Increase patient and visitor awareness of water conservation (e.g., signs in patient rooms and restrooms, publicize water conservation policy).

- Locate and correct drips, leaks, and unnecessary flows in bathrooms, laundry, kitchen, labs, etc.

- Repair/adjust flush mechanisms on toilets so that they work as designed.

- Irrigate grounds and wash vehicles less often.

Domestic Water Reduction

- Toilets and urinals. Install toilet tank water displacement devices on older models or replace inefficient toilets and urinals with low-flow models. Retrofit flushometer toilets with water-saving diaphragms. Before selecting new equipment (e.g., low flush, dual flush), check out third party tests to determine actual effectiveness. Under third party maximum performance tests, toilets are tested to see how much waste they will flush away instead of their ability to clear away a minimal amount of media.

- Sinks and showers. Install flow reducers (<2.5 gpm) and aerators on applicable plumbing fixtures. Install automatic shutoff valves or motion sensor-activated faucets.

Process Equipment

- General. As appliances and equipment wear out, replace with air cooled or water-saving models.

- Steam traps. Steam traps are automatic valves that release condensed steam (condensate) from a steam space while preventing the loss of live steam. They are present throughout many facilities (air and water heating, kitchen, laundry equipment, sterilizers, autoclaves, etc.). Once steam has transferred heat and has condensed to become hot water, it is removed by the trap from the steam side as condensate and either returned to the boiler via condensate return lines or discharged to atmosphere (a wasteful practice). Faulty or inoperative steam traps can waste water and energy. Develop a steam trap inspection plan. Replace faulty steam traps with effective, low-maintenance units.

- Sterilization equipment.

- Install steam condensate temping systems (makes use of high-temperature-sensing probe that causes use of the minimal amount of injection water into discharge leaving the sterilizer) on vacuum and gravity sterilizers (retrofit kits are available).

- Replace water-induced vacuum devices on sterilizers with electric pumps (retrofit kits are available).

- Film processors. Replace or retrofit continuous flow-through systems with flow control equipment.

- Refrigeration equipment. Recover condensate from refrigerators, freezers and ice makers for reuse.

Water Reuse

- Radiation therapy linear accelerator (creates high-energy radiation to treat cancers). Water can be taken from the reject side of the linear accelerator heat exchangers and pumped to the facility’s cooling towers and reused for evaporative cooling.

- Reverse osmosis (RO). Reject water produced in the RO process can be reclaimed for non-miscellaneous potable water use or in the cooling towers.

Water Supply/Systems

- Water pressure. Install pressure-reducing valves where system pressure is higher than 60 psi.

- Cooling towers.

- Reduce excessive blowdown. Operate cooling towers near manufacturer recommended level of total dissolved solids (TDS).

- Consider using ozone as a cooling tower treatment to reduce water used for make-up.

- Boiler. Return steam condensate to boiler for reuse.

- Sprinklers.

- Minimize water use for irrigation (e.g., adjust repair sprinklers, install wet weather shutoff and/or soil moisture controllers).

- Investigate sources of used water.

Kitchen

- Dish washing.

- Other.

- Turn off the continuous flow used to clean the drain trays of the coffee/soda beverage island (only clean the trays as needed).

Laundry

- Washers.

- Reprogram machines to eliminate additional rinse cycles, if possible and not restricted by the health department.

- Wash full loads only or reduce water levels to minimize water required per load of washing.

More Information

An abundance of water conservation methods and techniques applicable to healthcare facilities can be found by Googling the Internet. The following are sites we found to be particularly useful resources. (Please note that links to commercial sites or commercial product literature are offered as examples of available information and should not be considered an endorsement. If you have information you would like see posted here, contact Lisa Stobierski).

- WaterSense is a relatively new voluntary public-private partnership sponsored by the EPA to promote water-efficient products and practices. WaterSense will provide businesses with a simple way to make smart choices, with the confidence that the products will perform at least 20 percent more efficiently than their wasteful counterparts.

- WaterSense Commercial Information. Learn more about water use in different types of commercial buildings like hotels, hospitals, office buildings, schools, and restaurants.

- WaterWiser—The Water Efficiency Clearinghouse: This American Water Works Association (AWWA) website provides water conservation, efficiency, and demand management information

- Green Guide for Health Care Series - Water Conservation Strategies: Practice Greenhealth teleconference resources pertaining to water conservation, including a downloadable presentation and case studies.

- Water Efficiency Practices for Health Care Facilities. NH Dept. of Environmental Services provides water conservations tips for

- Domestic/Sanitary Water Efficiency Practices

- Sterilizing Equipment Water Efficiency Practices

- X-Ray Equipment Water Efficiency Practices

- Kitchen/Cafeteria Water Efficiency Practices

- Outdoor Water Efficiency Practices.

- WATER EFFICIENCY: TIPS FROM THE HEALTHCARE AND HOSPITALITY SECTORS, 5/27/2022

In a recent peer exchange, Better Buildings partners from the hospitality and healthcare sectors

discussed challenges and solutions related to water efficiency, conservation, and safety. The event

brought together Better Buildings partners and affiliates, including Hilton, Travel + Leisure, the University

of Maryland Medical Center (UMMC), the University of Nebraska Medical Center (UNMC), Healthcare

Realty, Kaiser Permanente, DaVita, the Dept. of Veterans Affairs (Erie Medical Center), and the American

Hospital and Lodging Association (AHLA). Partners shared opportunities and best practices for improving

water efficiency and conservation (both indoors and landscaping), submetering and data collection, and

water safety.

|

Facilities Management—Water

Conservation

Facilities Management—Water

Conservation